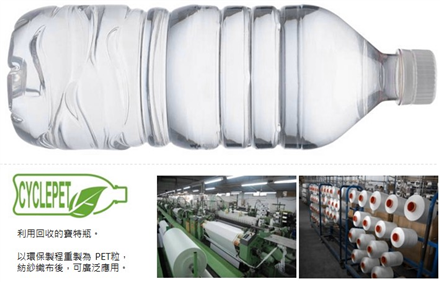

| CYCLEPET |

|

uses 100% post-consuming PET beverage bottles to make recycled PET yarn for the fabrics. After being sorted and cleaned up, these PET bottles will be pressed as PET bricks and then crushed as chips. Then, the chips will be re-polymerized into pellets. These pellets are the raw material of recycled PET yarns. In the next step, PET yarn is woven into fabric and finished for all kinds of textile products, including T-shirts, hats, gloves, suits, handbags, carpets etc. Because of the process of the re-polymerized process, the quality of CYCLEPETTM yarn is as stable as the original polyester yarn. Using recycled PET fabrics instead of new polyester fabrics reduces the output of wasted water, and cuts down on the consumption of crude oil significantly. Also, all of the CYCLEPET fabrics is manufactured in eco-friendly process and meet bluesign system standard. |