-

About Us

-

News Center

-

Products

-

Certificate

-

Authorize Brands

-

contact us

THE NEW SUSTAINABLE PRINTING

2017 May

HO YU set up new Printing System in-house. It includes Digital Printing, Cool Transfer printing and Gravure Transfer Printing. All these three printings together is a nice integrated printing system which is a total solution for Printing and support to each other for different fabrics.

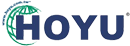

The Digital Printing technology is being improved yearly. When we do the Digital Printing for nylon or cotton, we will need to have finishing process from Steaming, Soaping and then go for Heat Setting after printing. But, for the polyester, we may not need to do Steaming and Soaping after printing and just go for Heat Setting directly.

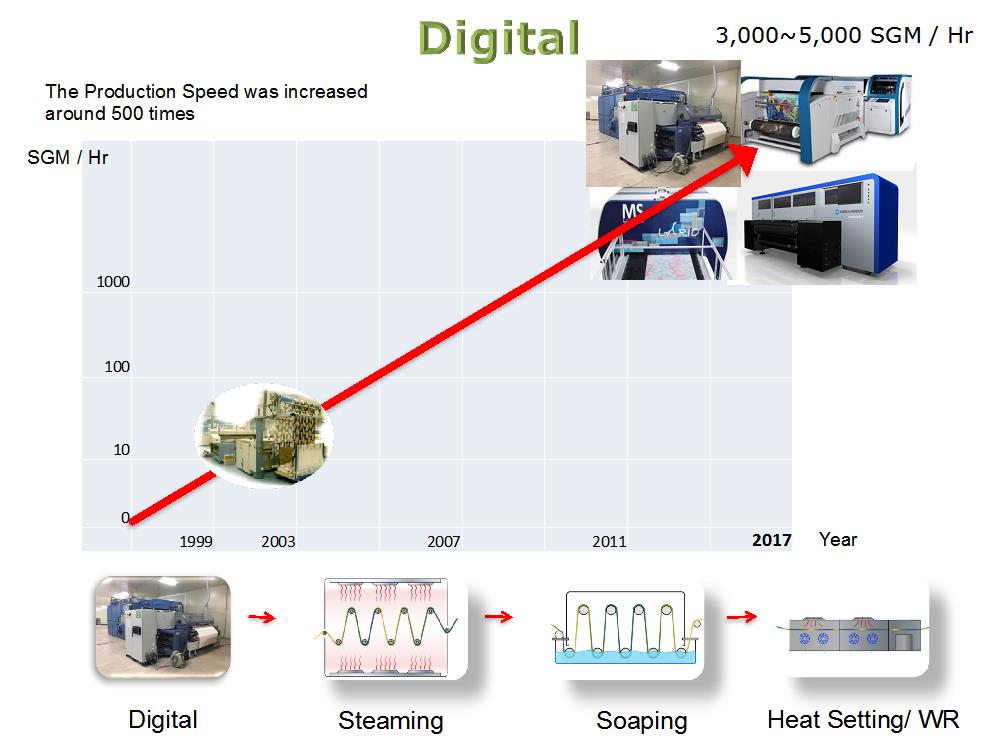

Here is the process of the Cool Transfer on nylon by cylinders. First of all, engraving cylinders, and patterning on the paper and then cold transfer the patterns onto fabrics. The transferring process is the same as we do heat transfer on polyester but at low temperature thus we call it Cool Transfer.

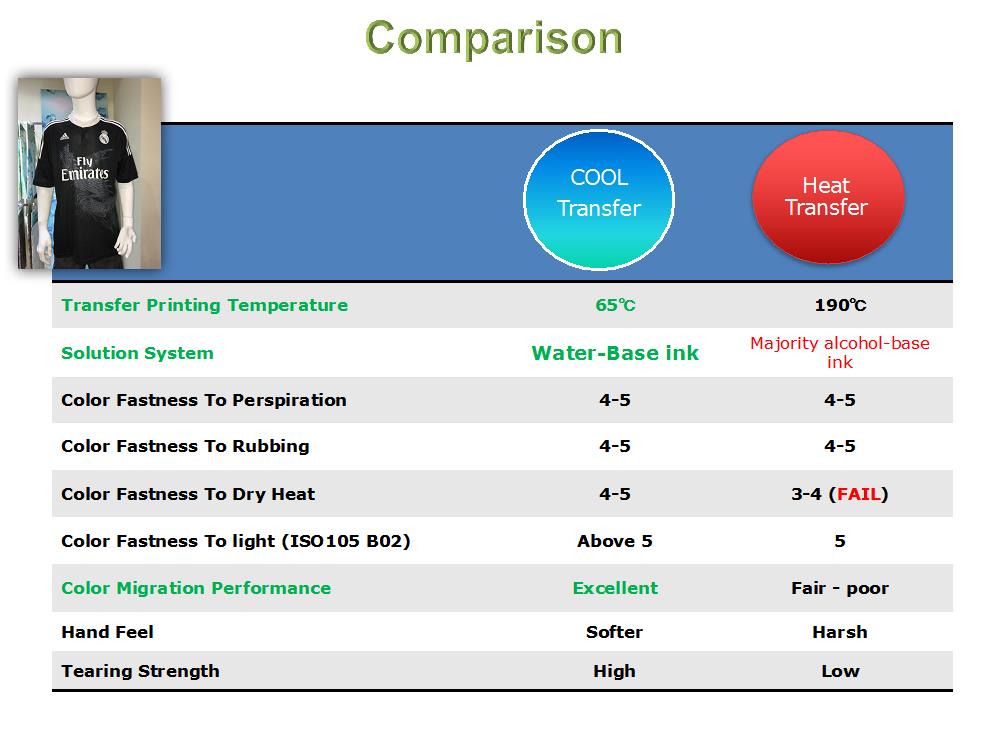

The main differences between Cool Transfer on nylon and heat transferring on polyester: the transfer printing temperature is room temperature for nylon and 190°c for polyester thus it saves energy here; the Cool Transfer is using water-base ink and it is more ecofriendly than heat transfer which is using Alcohol-base ink. The color migration and the hand feel of the Cool Transfer printed fabric is much better than by hear transfer.

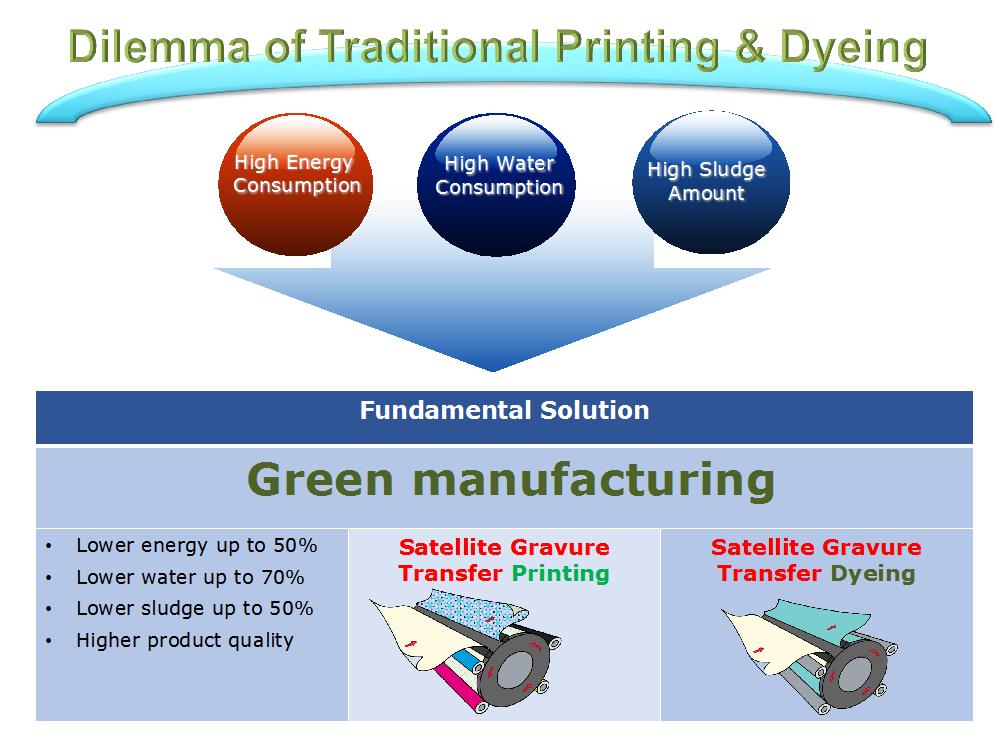

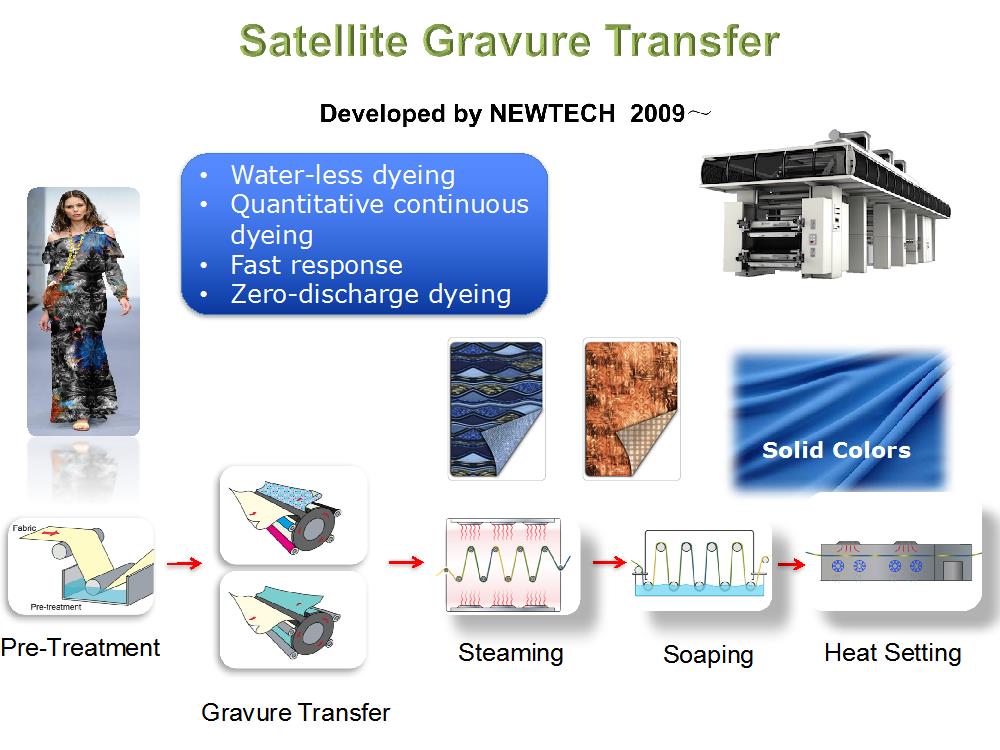

Because of the environmental pollution issue, textile technicians are trying to reduce the energy and water consumption and also the sludge after dyeing on the traditional dyeing and printing. Here is a new solution for textile industry. It is Satellite Gravure Transfer. This technology can do transfer printing and transfer dyeing as well. It has two big drums and each drum carries small cylinders which is the similar cylinders are used in Cool Transfer but without transfer paper and it prints fabric with water-base ink onto fabric directly. By this printing concept, we can save around 50 to 70 % on energy, water consumption, and sludge reduction.

The technology of Gravure Transfer is the same as printing our banknotes. It has several benefits: high resolution, smooth color gradation, rich in colors, and high production output.

The Gravure Transfer can do transfer printing and transfer dyeing with the same technology. It is water-less dyeing; Quantitative continuous dyeing; Fast response; Zero-discharge dyeing

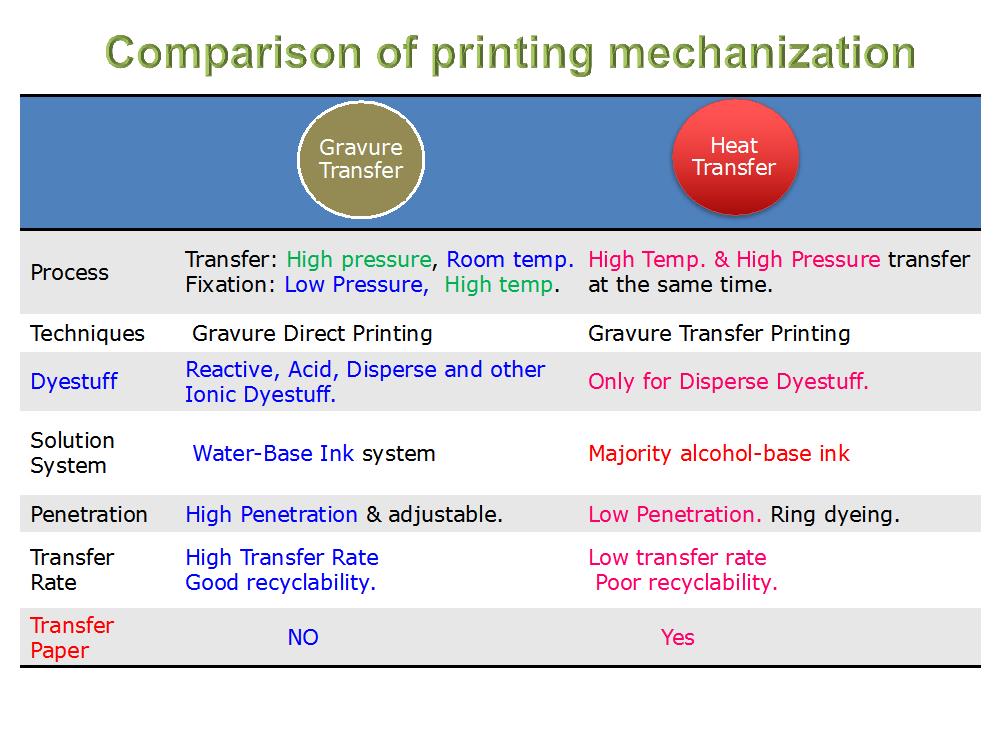

If we compared some performance between Gravure Transfer and heat transfer, we can understand the benefit of Gravure Transfer well. The Gravure Transfer is printing fabric at high pressure with room temperature and the printed fabric is fixated in low pressure with high temperature. It can be applied with reactive, acid, disperse and other Ionic dyestuff in water-base. And it has excellent transfer rate at 95% which is higher than Heat Transfer. Again, it prints fabric by cylinder directly and it doesn’t need transfer paper.

Here we did some performance comparison between Gravure Transfer

with heat transfer as this slide. It has better penetration effect and better dyestuff pick up than Heat transfer. The color can be more rich as well.

The concept of the Gravure Transfer technology is printing fabric instead of dyeing fabric to do the solid color. Thus, the water consumption is limited in the dyestuff tank for each color only. This technology can use different dyestuff for various material. We focus on the light weight nylon printing at this moment. The dyestuff exhaustion is more than 95%. It prints fabric at room temperature and no need to boil the water with dyestuff.

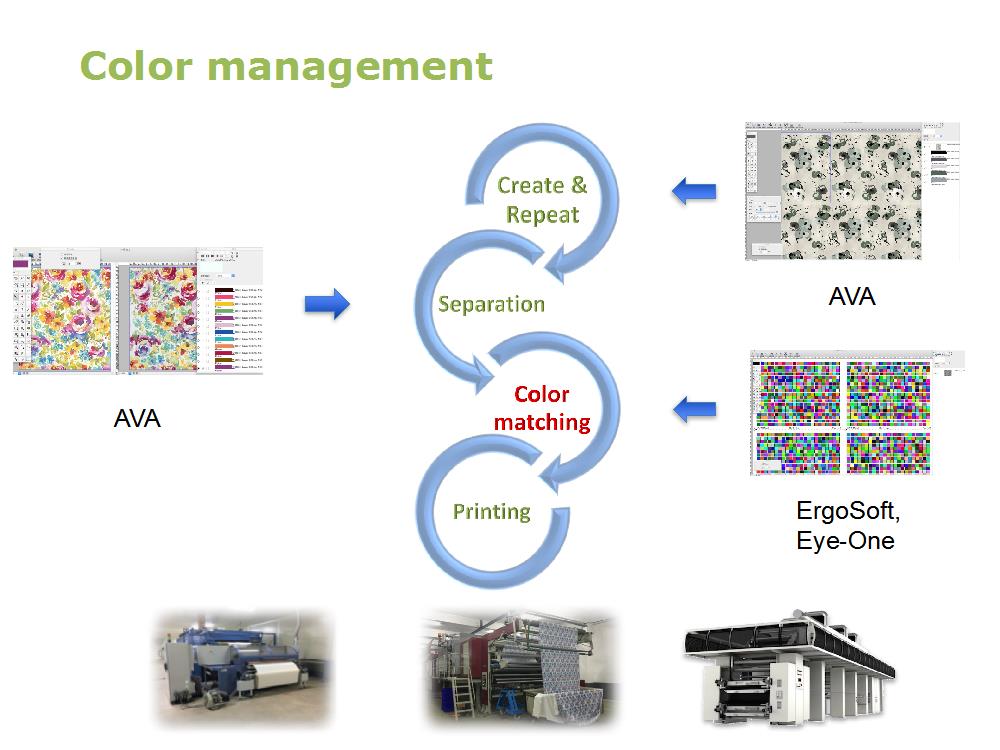

I would like to mention the importance of the color management among the different printings. Thus we can use different printings technologies efficiently and manage the color among different materials and match to each other well.